IMACHINE - Mobile Field Robotics Platform

Robotic Multifunctional UGV / Off-road Autonomous Vehicle Platforms

IMACHINE - Mobile Field Robotics Platform

Robotic Multifunctional UGV / Off-road Autonomous Vehicle Platforms

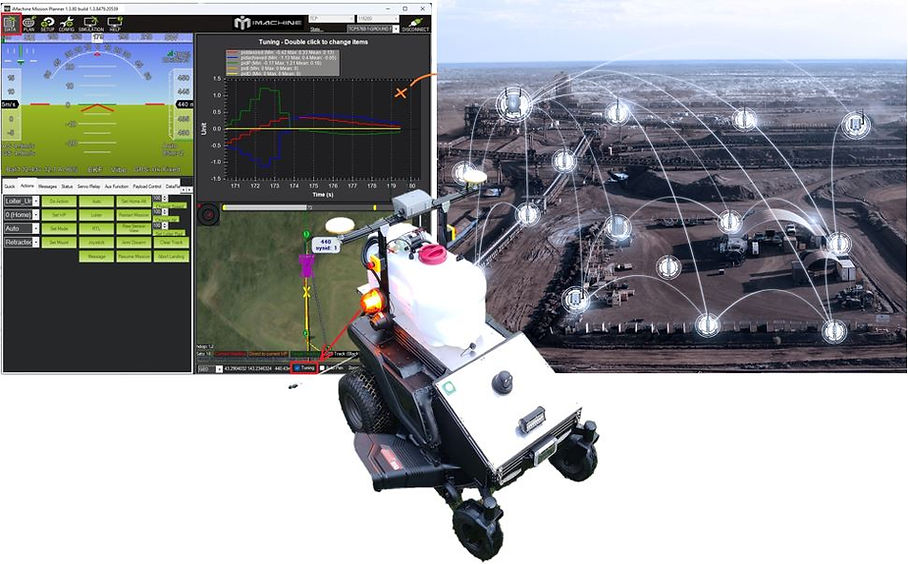

IMachine has developed and commercialised state of the art Fully Autonomous Robotic Vehicle and Teleoperation technology for Offroad Utility Vehicles, Tractors, Construction Machinery, Mining Operations, Exploration Vehicles and Agricultural Machinery. Classed as a UGV (Unmanned Ground Vehicle), these platforms are more advanced robotic systems that can operate on various terrains and environments without human intervention, when a predetermined 'mission' has been planned by a human operator initially. The UGV will perform it's mission safely, avoiding obstacles and stopping for safety hazards along the way, as well as more advanced navigation features, for complex outdoor environments, with natural and man made obstructions.

They are equipped with a range of sensors and navigation technologies to make decisions and adapt to new situations, equipped with sophisticated sensors and computer systems that allow them to understand and navigate through unstructured environments. We have engineered a highly reliable and safe battery system and autonomous charge coupling (docking) system, these machines are 100% electric and Zero Emissions.

IMACHINE's Australian Designed and Made range of intelligent, modular autonomous Rover, AGV/UGV Systems, has a full suite of tightly integrated industrial grade electronics, software and equipment, including:

-

Ultra long range radio connectivity and satellite backhaul;

-

Real-time payload automation and vehicle teleoperation;

-

On board Edge Computing with industrial grade Real-time controller and software for high speed navigation, inertial control, motor and steering control;

-

Precision fusion GPS, IMU, AHRS, LiDAR and stereoscopic vision system guidance;

-

4 x high resolution cameras (front, left and right sides and rear);

-

Under carriage camera (for viewing ground or underneath the vehicle for in mission camera inspections);

-

High level of safety and a complete robotics mission control platform;

-

Weatherproof IP55 rating (or higher as needed);

-

Zero turn (360deg turning on axis) or more precision steering systems available;

-

Large 200AH 56VDC Lithium (LiFePO4) Battery system for run time of 8+ hours with a full payload of up to 200kg;

-

Multiple payload options;

-

Smaller and larger scale platforms available to suit application requirements;

-

Mission Control and Planning software for complex mission setup and automation;

-

Several layers of safety systems to ensure the machine operates safely and securely;

-

Highly available spare parts and back to base support.

The all electric AGV/UGV platform is highly adaptable to can be utilised for fully autonomous vehicle, rover or utility applications in a wide array of use cases, including mining operations and exploration, agriculture and grounds keeping, long range industrial inspection missions.

IMACHINE's service offering can augment robotics startups and tech companies to fast-track their R&D, or accellerate in house programs for industrial, mining, agriculture and construction operations, freeing up workers for more important tasks, that reduces time spent on lower level tasks that are traditionally handled by machine operators in the field.

IMACHINE Field Robotics Enablement Platforms

Field Robotics - Autonomous Exploration, Crawler Platforms & R2E (Robot to Everything)

IMACHINE have developed state of the art Fully Autonomous Robotic Vehicle and Teleoperation technology for robot connectivity, exploration rovers, custom off-road robotic AGV/UGV systems, Industrial Grade Crawlers, Mining and Construction Machinery. IMACHINE's Australian Designed and Made range of intelligent, modular autonomous systems, with precision fusion guidance and a complete robotics control platform can be utilised for a wide array of automated vehicle applications.

IMACHINE's Australian Designed and Made range of intelligent, modular autonomous Crawler, Rover and AGV/UGV Systems, has a full suite of tightly integrated industrial grade electronics, software and equipment, including:

-

Ultra long range radio connectivity and satellite backhaul;

-

Real-time payload automation and vehicle teleoperation;

-

On board Edge Computing with industrial grade Real-time controller and software for high speed navigation, inertial control, motor and steering control;

-

Precision fusion GPS, IMU, AHRS, LiDAR and stereoscopic vision system guidance;

-

4 x high resolution cameras (front, left and right sides and rear);

-

Under carriage camera (for viewing ground or underneath the vehicle for in mission camera inspections);

-

High level of safety and a complete robotics mission control platform;

-

Weatherproof IP55 rating (or higher as needed);

-

Zero turn (360deg turning on axis) or more precision steering systems available;

-

Large payload or main drive battery and fast charging system with 50AH/100AH/200AH (optional sizes) 56VDC Lithium (LiFePO4) Battery system for run time of up to 8-12+ hours with a full payload, pending application specifics;

-

Multiple payload options, standard PTO and 3 point hitch for typical tractor use cases;

-

Smaller and larger scale platforms available to suit application requirements;

-

Mission Control and Planning software for complex mission setup and automation;

-

Several layers of safety systems to ensure the machine operates safely and securely;

-

Highly available spare parts and back to base support.

The all electric AGV/UGV platform is highly adaptable and can be utilised for fully autonomous tractor, construction or mining vehicle, rover or utility applications in a wide array of use cases, including mining operations and exploration, landfill and waste management, agriculture and grounds keeping, long range industrial inspection missions.

Overarching functional options include:

-

Teleoperated, Fully-Autonomous or semi-autonomous control;

-

Modular payload and custom automation options for unique applications.

-

Local Radio Direct Controller, Field Computer (GCS) controller, Back to Control Room and Back to Base monitoring and control options are available.

-

Full integration with PLC/SCADA and existing control systems is possible.

IMACHINE's platform provides a fully managed platform for remote field robotics and autonomous vehicle operations, that can help robotics developers, operations managers and stakeholders to:

-

Improve profitability;

-

Increase operational yield by running 24/7;

-

Precision technologies and fully customisable control system for automation of payloads and integration;

-

Free up operators and workers for higher level tasks;

-

Increase safety and reduce operator exposure to chemicals or other hazards.

IMACHINE's service offering can augment a industrial, mining, government and construction operations.

Unlocking the Potential of Advanced Smart Fleet, Remote Operated Vehicles, Mobile Machinery & Asset Operations through Industry 4.0 Technology

At DAYTECH we leverage our substantial engineering experience and portfolio of modular hardware and software to deliver turn-key solutions. By consulting closely with your team to listen to your needs, we can design, develop, manufacture, commission and deliver innovative projects to meet your individual site, fleet and process requirements with the following capabilities:

-

Remote operations and control systems;

-

Vehicle and mobile machinery precision GPS localisation, IMU based speed/heading/acceleration tracking, navigation systems integration and telematics;

-

Continuous mobile machinery payload measurement and automation;

-

Wireless Vehicle to Process (V2P) integration;

-

Real-time LiDAR based Object Detection & Collision Avoidance (ODCA) safety systems, for in vehicle touch screen visualisation and remote web based integration;

-

Integrated Drone mapping & inspection deliverables and services;

-

Wireless Sensor Networks (WSN), for process and environmental systems;

-

Multifunctional IIoT-SmartNodes, to connect vehicles, mobile machines, workers, fixed plant and equipment, processes and the environment in real-time;

-

Industrial edge computing and gateways for centralised and decentralised connectivity of assets in real-time for remote management of operations;

-

Gear up for the next generation of autonomous vehicles, with Teleoperations technology, for critical activities, such as drilling and blasting, that improves safety.

These ruggedised solutions are implemented by our team of engineers and used by our customers as a platform for mission critical Industrial IoT, remote operations and process control, remote Drone/Rover robotics inspection and vehicle automation. Our Platforms allow the connection and and payload automation for mobile vehicles, disparate process and critical assets, complete with environmental and equipment condition monitoring and automated or semi-automated inspection and compliance options.

Knowledge truly is power and DAYTECHs technologies provide this specifically for the energy, resources and waste industries. Have visibility and control at your fingertips from anywhere in the world in real-time, improve safety for workers and debottleneck the fixed and mobile plant and equipment operations for increased efficiency.

DAYTECH's Solutions for Vehicle, Mobile Machinery and Fixed Asset Connectivity: Empowering Efficiency and Safety.

VEHICLE, MOBILE EQUIPMENT & ASSET - DIGITAL REMOTE OPERATIONS

Remote Vehicle tracking, telematics, Wireless Sensing, Payload Automation and Control Systems, Engineered IIoT and LiDAR based Anti-Collision Safety Systems.

Gain insight into your equipment and process. Reduce CapEx AND OpEx, while implementing highly reliable Remote Automation Solutions

-

Remote Operational Command & Control Platform:

-

Maximize plant efficiency and visibility with real-time condition

monitoring, wireless sensing, and connectivity. -

Improve process control, industrial automation, safety, and

maintenance to reduce downtime and drive higher ROI. -

Secure Remote Operations, via private connected web-based SCADA

and 3D modelled process ‘digital clones’.

-

-

Site & Asset Management, Mapping, Modelling and Reliability:

-

Connect and remotely monitor site conditions and critical equipment

conditions in real-time, with options for 3D and 2D drone modelling. -

Real-time truck payload, waste cell level and volume calculations.

-

Wireless or drone-based condition monitoring and analysis, such as

vibration, thermography & AI imaging for integrity inspection. -

Reduce downtime through predictive maintenance.

-

-

Environmental Monitoring, Compliance & Engineering:

-

Weather station integration, geotechnical and slope monitoring.

-

Real-time wireless air, dust and gas detection for safety, alarming and

automated leak detection, through smart sensor technology. -

Monitor vegetation cover, land rehabilitation progress, and ground

water bodies within and around the landfill area to support

sustainable land management practices.

-

-

Autonomous Off-Road Vehicles, Drones, Rovers & Field Robotics:

-

Connect, monitor, inspect, control, and automate mobile plant

machinery, vehicles, drones, and field operations - anywhere, anytime. -

Lay the foundations for autonomous vehicles.

-

Unify mobile ground robotics and drone operations in harsh

environments for reliability and innovation.

-

To contact us regarding your enquiry for engineering solutions and for a free consultation with an engineering expert, please fill in the contact form below and we will respond: